Light Guide Plates (LGP)

Modernizing Lighting Solutions

Introduction

Architectural lighting continues to evolve toward slimmer, more efficient, and low glare solutions. At the core of this evolution is Light Guide Plate (LGP) technology, which transforms directional LED light into uniform illumination, enabling sleek designs without compromising performance. By harnessing the principles of total internal reflection and microstructured surfaces like micro-dots, LGPs provide uniform and energy-efficient lighting. This article will explore the intricacies of Light Guide Plate technology, its applications in modern lighting fixtures, and its potential to transform the way we illuminate our spaces.

What is a Light Guide Plate (LGP)?

A Light Guide Plate (LGP) is an optical component commonly used in the manufacturing of backlights for LCD displays and luminaires. In lighting applications, it is typically an optical-grade acrylic sheet embedded with an array of micro-dots or other microstructures. These features help distribute light evenly by guiding it from edge-mounted LEDs and emitting it perpendicularly through the front surface. The intended application influences the choice of microstructure pattern. In Beta-Calco’s implementation, a uniform series of matte dots is etched into the sheet, minimizing light loss and producing a more evenly illuminated surface, often referred to as a dotted sheet.

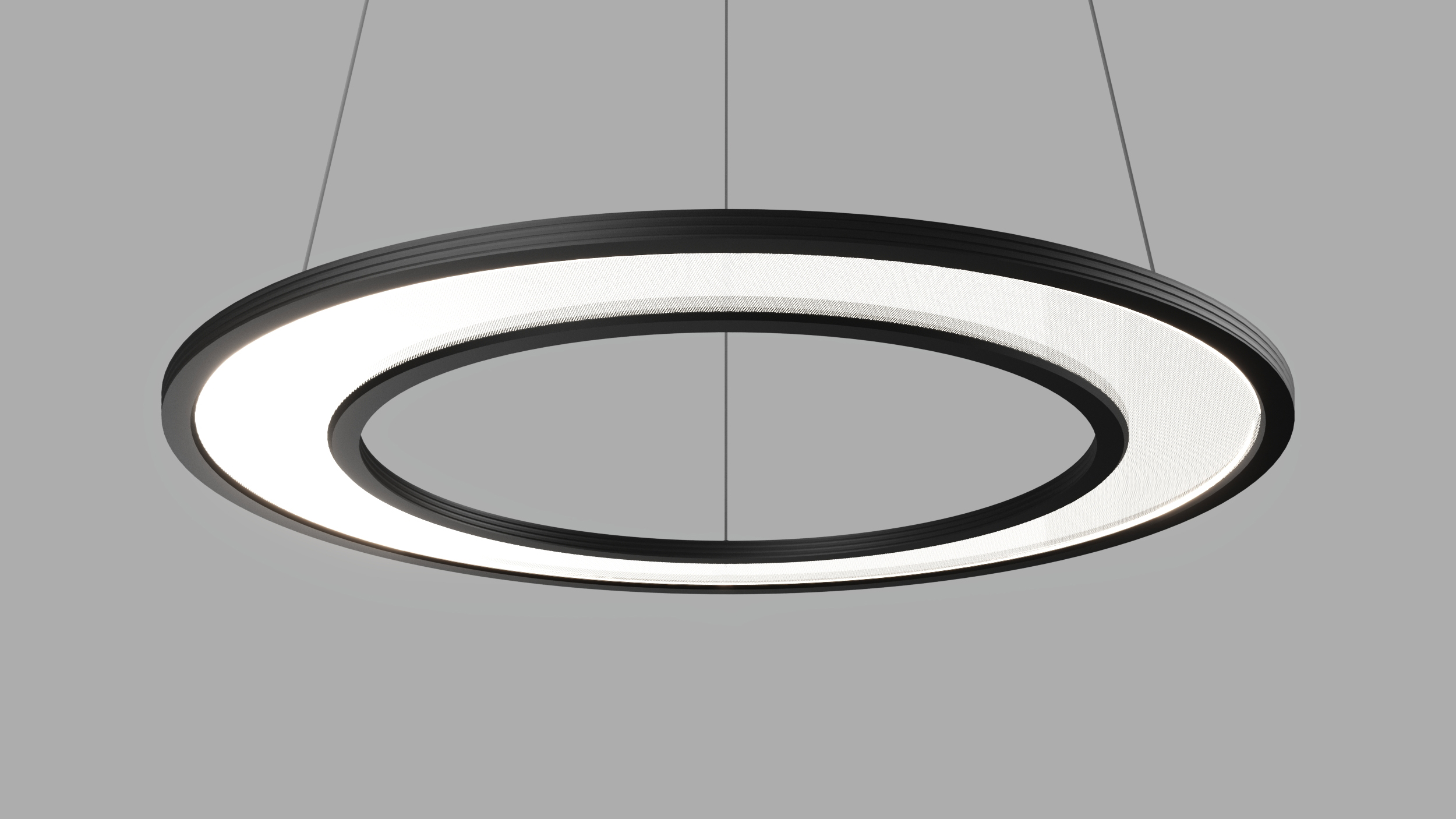

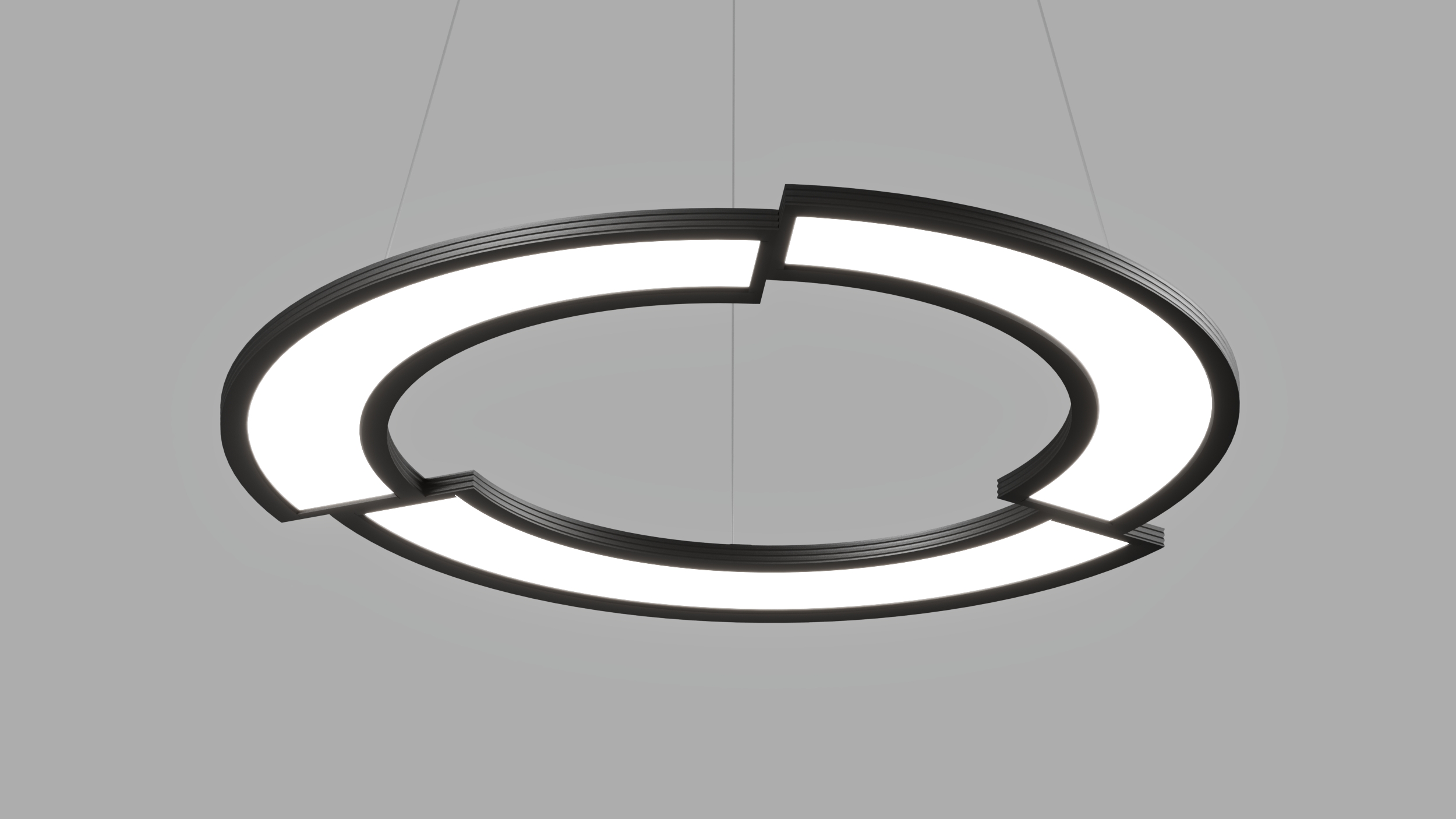

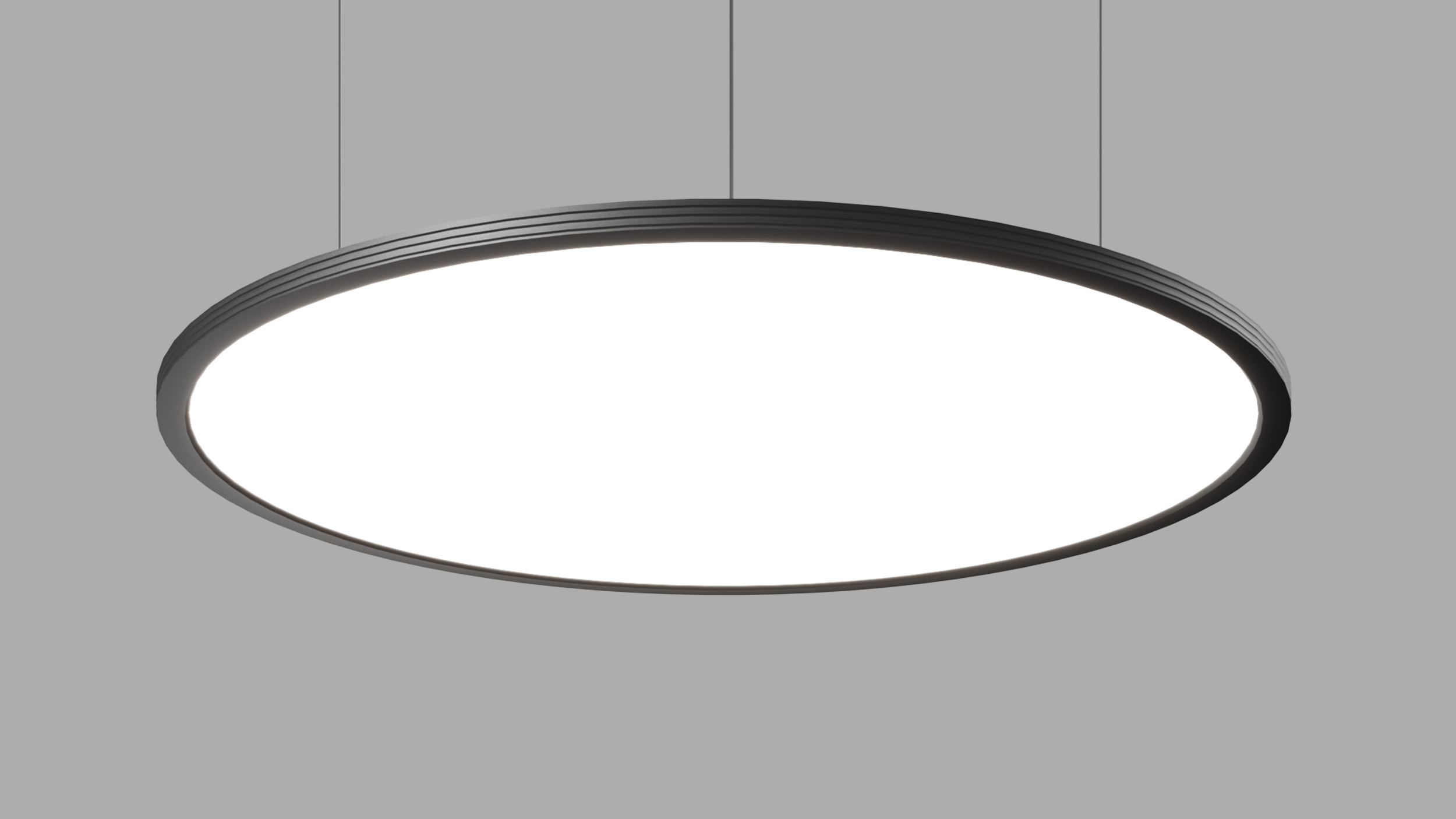

Light Guide Plates are used in a wide range of illumination applications, particularly in settings that require a slim, energy-efficient light source. Being completely transparent and colorless, LGPs offer high light transmission and accurate output. Beta-Calco uses optical-grade clear acrylic to achieve optimal results in key products such as the RING BLADE, SWITCH, and RING DISC series. The primary function of an LGP is to guide light beams in order to enhance brightness and maintain uniform light distribution.

To ensure optimal light extraction and uniformity, the dot patterns on an LGP are precisely calculated and the fixture’s behavior is simulated by experienced engineers. Once the pattern is finalized, it moves to production, where micro-dots are engraved directly onto the surface of the pre-cut clear acrylic sheet. Compared to printed patterns, engraved patterns provide greater durability and consistency, especially in applications requiring long product life and stable optical performance.

How Do LGPs Work?

Light Source and Entry

Microstructured Surface

Light Diffusion and Emission

Reflective Layer

Applications

Why is LGP Technology Important?

The unique value of a Light Guide Plate (LGP) lies in its ability to transform directional LED light into a broad, uniform, and low glare light source, even within ultra-thin luminaires. Key benefits include:

Uniform and Low Glare

LGPs deliver uniform illumination without hotspots and low glare, creating a smooth, visually comfortable surface. Beta-Calco fixtures using direct-indirect achieve UGR levels below 19.

Energy and Cost Efficiency

By transmitting light with minimal loss, LGPs support lower power consumption and reduce operational costs over time. Their long lifespan and reliability contribute to long-term savings in both commercial and residential applications.

Sustainability

Durability and Material Integrity

Slim, Lightweight and Modern

Versatility

Conclusion

Light Guide Plate (LGP) technology continues to expand the possibilities in architectural and decorative lighting. By converting the directional output of LEDs into uniform, low glare illumination, LGPs provide a practical solution for creating slim, efficient, and visually refined fixtures. Their versatility makes them a valuable tool for designers looking to balance performance with creative freedom.

Understanding how LGPs work and what contributes to their effectiveness helps specifiers and lighting professionals make informed decisions that support long-term efficiency, sustainability, and design intent. As the demand for smarter, more streamlined lighting solutions grows, LGPs will remain a key component in creating environments that are both functional and visually cohesive. At Beta-Calco, products like our RING BLADE series are a shining example of fixtures that perfectly balance both visual form and function.